Laser Level Manufacturer & Supplier

Geemace is a fully integrated manufacturer, specializing in the research, production, and supply of high-precision laser levels. With over 25 years of manufacturing expertise, we are dedicated to providing products that enhance your project’s accuracy and efficiency, while ensuring each product undergoes rigorous quality testing. Our laser levels are widely used in construction, renovation, civil engineering, and interior design, meeting the precise measurement needs of various industries. As a manufacturer, we offer a comprehensive range of models, each tailored for different application scenarios.

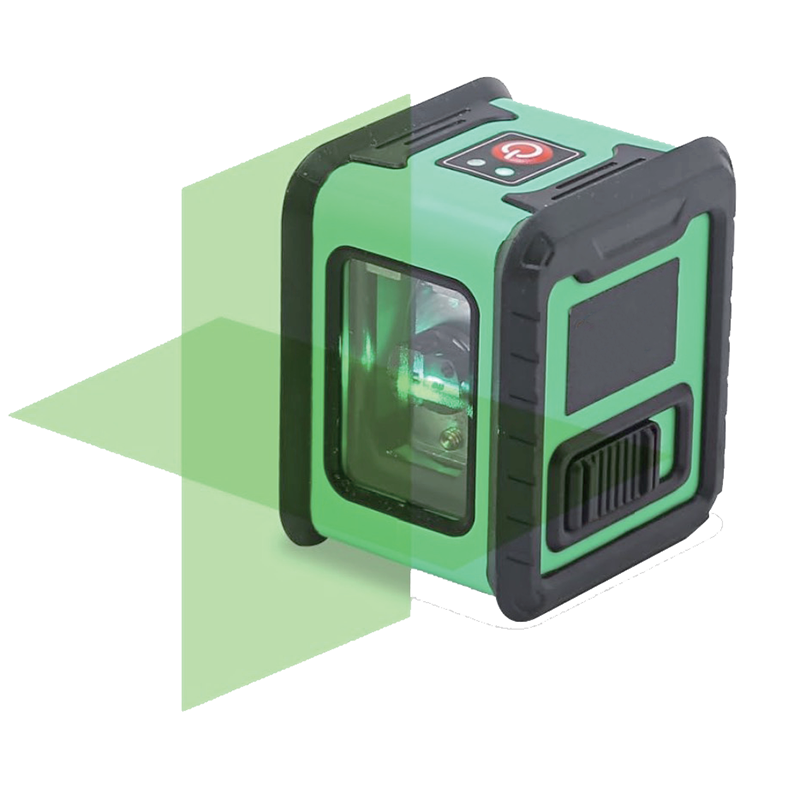

Laser Level

Still not finding what you're looking for? Contact our consultants for more available products.

Product Features

Extensive Industry Experience

With over 25 years in the laser level industry, Geemace brings deep knowledge and expertise to every product we create. Our extensive experience ensures that you receive reliable, innovative laser levels that have been perfected through years of research and development. This means fewer malfunctions and longer service life, saving you time and reducing costs on replacements and repairs.

High-Quality Materials

We use only the highest quality materials in the production of our laser levels, ensuring durability and superior performance. Our commitment to quality means that our tools are built to withstand demanding use, providing consistent and precise measurements over time. This enhances your productivity and ensures that your investment yields maximum returns.

Customization Options

We offer customizable designs and specifications to meet your brand’s specific needs and preferences. Customization enables you to create a distinctive product line that stands out in the market, helping to build a stronger brand identity. This can attract more customers and boost your sales and market presence.

Competitive Pricing

Our laser levels are competitively priced, offering an excellent cost-performance ratio. By reducing your procurement costs, our competitive pricing allows you to achieve higher profit margins, making your business more profitable.

Global Reach

Geemace has a well-established distribution network, exporting to countries including Turkey, Eastern Europe, South America, and Russia. Our global reach ensures that we can efficiently deliver our products to you, wherever you are. Reliable logistics and timely delivery keep your operations running smoothly, minimizing any potential disruptions.

Exceptional Customer Support

Our dedicated customer support team is always ready to assist you, from initial inquiry to after-sales service. Exceptional customer support guarantees a smooth and hassle-free experience when working with us. Whether you need technical support, product information, or assistance with any issues, our team is here to help you every step of the way, ensuring your complete satisfaction.

Something you should know

I.how to use laser level on wall?

Step 1: Set Up the Laser Level

- Mounting: First, securely mount the laser level on a tripod or wall bracket, ensuring the device is stable and does not wobble. If you are using a self-leveling laser level, make sure it is placed on a level surface or firmly fixed to the bracket to ensure the proper functioning of the self-leveling feature.

- Power On: Next, turn on the laser level and wait for it to self-level. This step is crucial, as the self-leveling feature quickly ensures that the laser line is perfectly level. If your device is not self-leveling, manually adjust the instrument until the bubble vials indicate a completely level state.

Step 2: Adjust the Laser Line

- Horizontal Line: When working on horizontal installation tasks (such as installing tiles, hanging picture frames, or mounting shelves), adjust the laser level to the desired height. Use the horizontal laser line as a reference to ensure that multiple items are aligned on the same horizontal plane, avoiding any tilting or uneven heights.

- Vertical Line: For projects requiring vertical alignment (such as installing cabinets, aligning bookshelves, or other vertical structures), adjust the laser level to project an accurate vertical line. Ensure the laser line passes through the reference point, allowing you to easily follow this vertical line during subsequent operations.

Step 3: Mark Your Points

- Precise Marking: Once the laser line is in place, use a pencil or marker to mark the points on the wall where you need to drill holes, hammer nails, or perform other tasks. When marking, pay attention to accuracy, ensuring that all marking points are aligned with the laser line to achieve perfect alignment in the final installation.

Step 4: Carry Out the Installation or Other Tasks

- Preparation for Installation: After completing all the markings, ensure that you have all the necessary tools and materials ready. Carefully check the marking points and laser lines to confirm their accuracy and consistency.

- Execute Installation: Perform the installation tasks according to the laser lines and marking points, such as drilling holes, hammering nails, mounting objects, or fixing other items. Whether you are installing shelves, hanging picture frames, or laying tiles, always refer to the laser line to ensure that every component is precisely aligned with the lines.

II.how to use laser level without tripod?

Using a laser level without a tripod may require some creativity and alternative solutions, but with the right approach, you can still achieve precise alignment and complete your project successfully. Here are some methods to use a laser level without a tripod:

Method 1: Use a Wall Mount or Bracket

Many laser levels come with a wall mount or bracket designed to attach directly to walls, ceilings, or other surfaces. These mounts are adjustable, allowing you to position the laser level at any height you need, making it easy to project horizontal or vertical laser lines.

- Mount the Laser Level: Securely attach the laser level to the mount or bracket, ensuring it is stable and won’t wobble. Then, fix the mount to the wall at the desired height.

- Fine-Tune the Angle: After mounting, you may need to adjust the angle of the laser level to ensure the laser line meets your project’s alignment needs.

Method 2: Place on a Stable Surface

If you don’t have a wall mount, another option is to place the laser level on any stable, flat surface. This method is particularly useful for home projects or smaller tasks where quick setup is needed.

- Find a Stable Surface: Choose a flat, stable surface like a bookshelf, window sill, or table. Make sure the surface is steady and not tilted. Use a level or other tools to check if the surface is even.

- Adjust Height and Position: You can place books, wood blocks, or other objects under the laser level to adjust it to the correct height. If your laser level is self-leveling, just ensure the surface is approximately level, and it will automatically calibrate; if not, you’ll need to manually level it.

Method 3: Use a Magnetic Base

Some advanced laser levels come with a magnetic base, offering great flexibility, especially on job sites or in environments with metal structures. The magnetic base allows the laser level to stick securely to metal surfaces, ensuring it stays in place.

- Choose a Suitable Metal Surface: Attach the laser level to a metal surface, such as steel beams, metal studs, or any magnetic material. This method is particularly effective on construction sites or in workshops.

- Check Stability: While magnetic bases usually offer strong adhesion, make sure the surface is clean and flat to ensure the laser level remains stable and accurate.

Method 4: Use a Clamp

A clamp is a very handy tool that can secure the laser level to various objects such as ladders, door frames, or pipes. Using a clamp allows you to quickly set up the laser level in different environments.

- Attach the Clamp: First, attach the clamp securely to the laser level. Then, clamp it onto a sturdy object, such as a ladder rung or the edge of a door frame. Ensure the clamp is tight and won’t slip or loosen.

- Adjust and Align: After clamping, you might need to adjust the direction and angle of the laser level to ensure the laser line is at the correct position.

Method 5: Handheld Use for Temporary Tasks

For quick, temporary tasks, you can hold the laser level by hand. While this method may not offer the highest precision, it can be effective for small jobs where a perfectly straight line isn’t critical.

- Keep a Steady Hand: When holding the laser level, try to keep your hand as steady as possible to avoid shaking or shifting. You can complete marking or aligning tasks quickly while holding the level.

- Quick Marking or Adjustments: After making the necessary quick marks or alignments, proceed with the next steps as soon as possible to minimize the time spent holding the laser level.

Tips for Using a Laser Level Without a Tripod

- Frequent Alignment Checks: Without a tripod, it’s crucial to regularly check that your laser level is still properly aligned. Any slight movement or vibration can cause the laser line to shift.

- Ensure Equipment Safety: Make sure that the laser level is securely positioned to prevent it from falling or moving, which could lead to errors or damage.

- Use Auxiliary Tools: Whenever possible, use a spirit level, tape measure, or other measuring tools alongside the laser level to ensure maximum precision at every step.

By following these methods, you can efficiently use a laser level without a tripod and complete various alignment and installation tasks with ease. Whether you’re working on a home project or a professional job, these techniques will help you achieve accurate results.

III.how laser level works?

A laser level is a tool that helps you create perfectly straight lines on walls or floors, making tasks like hanging pictures, laying tiles, or installing cabinets much easier. The way it works is simple: inside the laser level, there’s a small device called a laser diode that emits a very straight beam of light. The laser level projects this beam onto the surface you’re working on, like a wall or floor, providing a guide to follow for precise alignment.

To ensure the laser line is perfectly level, most modern laser levels come with an automatic leveling feature. This is made possible by a small pendulum or sensors inside the device. When you place the laser level on an uneven surface, these components automatically adjust the angle of the laser level so that the laser line stays level. If the surface is too uneven, the automatic leveling won’t work, and the device will alert you to adjust it manually. This way, even if you’re not a professional, you can easily achieve accurate results.

IV.do laser levels work outside?

Laser levels can be used outdoors, but their effectiveness can be affected by sunlight, which makes the laser beam harder to see. Red lasers, which are common in many laser levels, are particularly difficult to see in bright sunlight. To overcome this, green laser levels are often used because green lasers are more visible in bright conditions. However, even green lasers can be hard to see in direct sunlight.

To solve this problem, a laser receiver is often used. A laser receiver is a device that can detect the laser beam even when it’s not visible to the naked eye. It emits a sound or displays a signal when it picks up the laser, helping you stay aligned even when you can’t see the beam.

Outdoor laser levels are typically built tougher, with features like water and dust resistance to handle different weather conditions. Many outdoor laser levels also have a self-leveling feature, meaning they can automatically adjust themselves to ensure the laser line is level, even if the ground isn’t perfectly flat.

So while using a laser level outdoors can be more challenging due to visibility issues, the right equipment and techniques can help you achieve accurate alignment.

V.why are laser levels so expensive?

Laser levels are expensive because they use advanced technology and precision components. Inside a laser level, there’s a highly accurate laser diode that emits a straight beam of light, which is crucial for aligning objects. To ensure the laser beam is perfectly level or vertical, the device is equipped with complex electronic sensors and an automatic leveling system, all of which are costly to produce.

Additionally, laser levels are often built to be very durable, able to withstand tough conditions like those found on construction sites. This durability requires high-quality materials, such as waterproof and dustproof casings, to protect the device from damage. High-end models might also include extra features like 360-degree laser projection or Bluetooth remote control, which add to the complexity and cost of manufacturing.

Therefore, the price of a laser level reflects its advanced technology, precision, durability, and additional functionalities, making it a reliable and high-quality tool for professionals.

VI.what does a laser level do?

A laser level helps you create perfectly straight reference lines on surfaces like walls, floors, or ceilings. Inside the laser level, there’s a small laser that emits a beam of light. This beam is extremely straight and forms a clear line on the surface you’re working on. The line can be horizontal, vertical, or even a cross of both, like a “+”. This helps ensure that tasks like hanging pictures, laying tiles, or installing shelves are done with perfect alignment, so nothing ends up crooked.

Many laser levels also have an automatic leveling feature, which means that even if you place the laser level on a slightly uneven surface, it will adjust itself to make sure the laser line remains perfectly level or vertical. This makes the tool very easy to use and ensures that your work is accurate, even if you’re not an expert. For any project requiring precise alignment, a laser level is an invaluable tool.

Get Free Quote

Contact us for a free quote and more expertise on customizing Power Tools.Geemace will provide the right solution for your project.

Get in Touch

- +86-15151555923

- info@geemace.com

Address

- Libet Company, Tianfen Town, Qidong City, Jiangsu, China